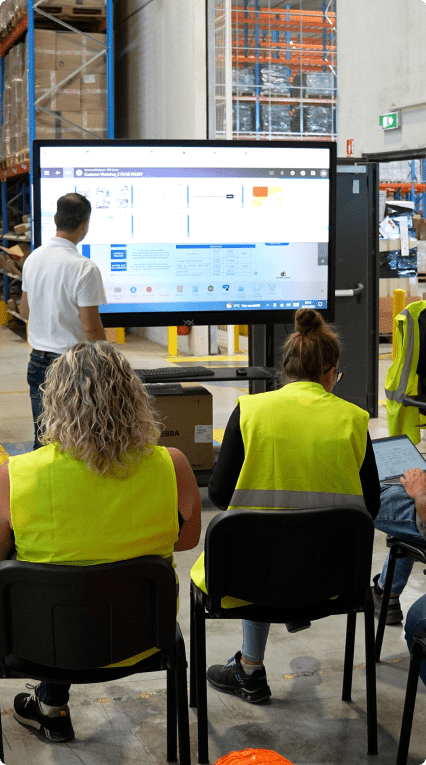

Collaborative management

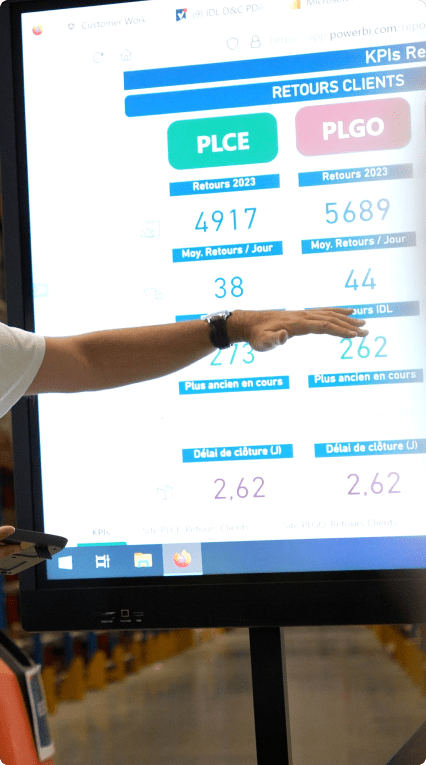

Collective intelligence delivers performance

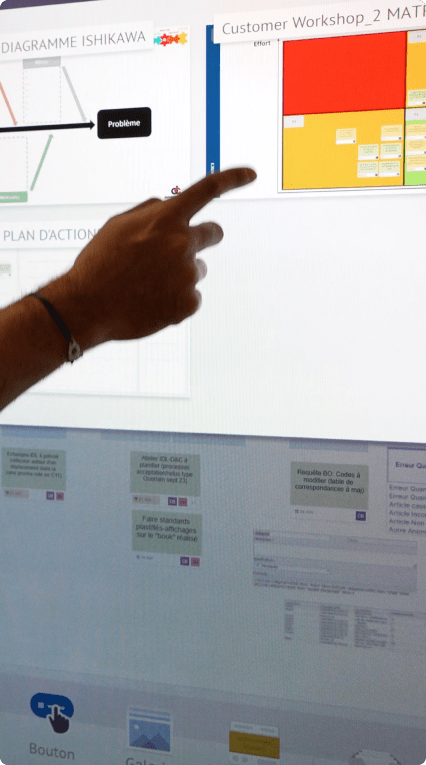

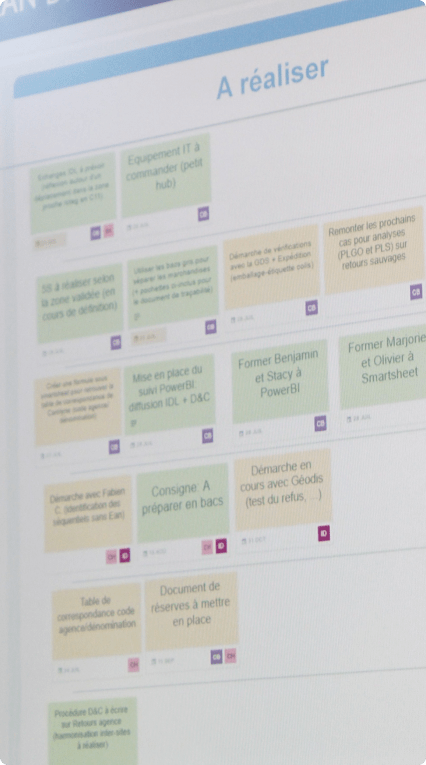

We develop collaborative management methods to improve our operational processes. They reduce organizational silos and combine all individual skills. Everyone plays a role in the process, which reinforces the commitment of employees and gives meaning to their work.