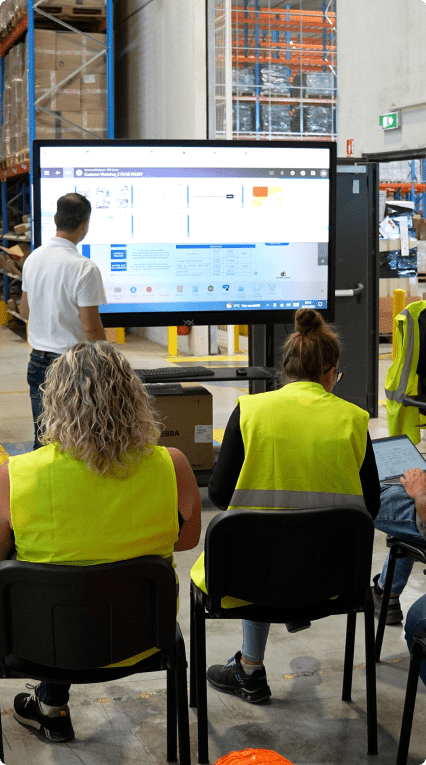

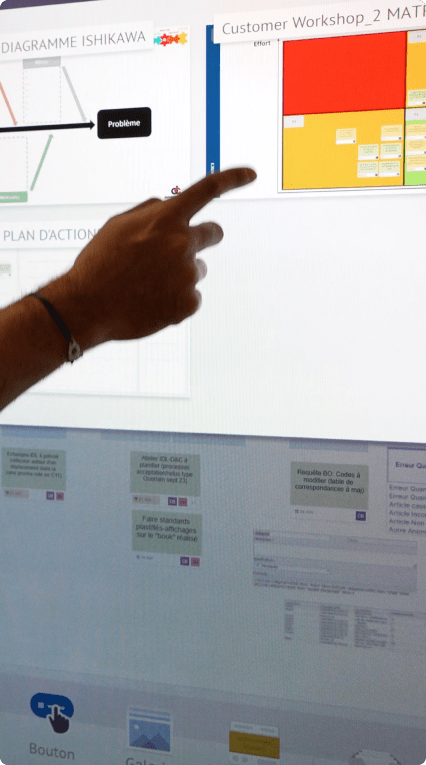

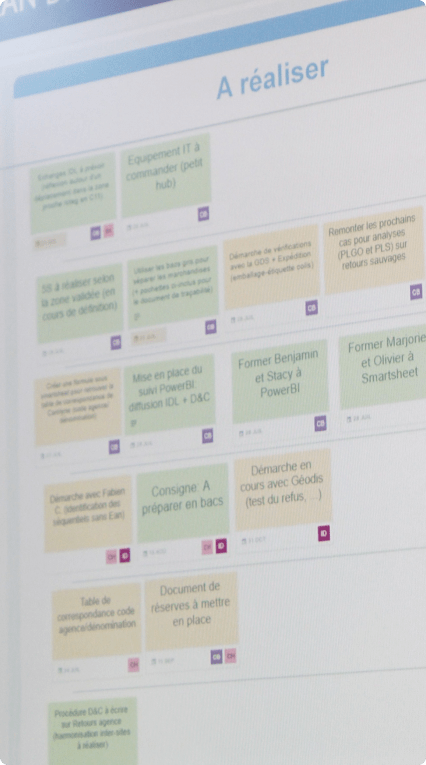

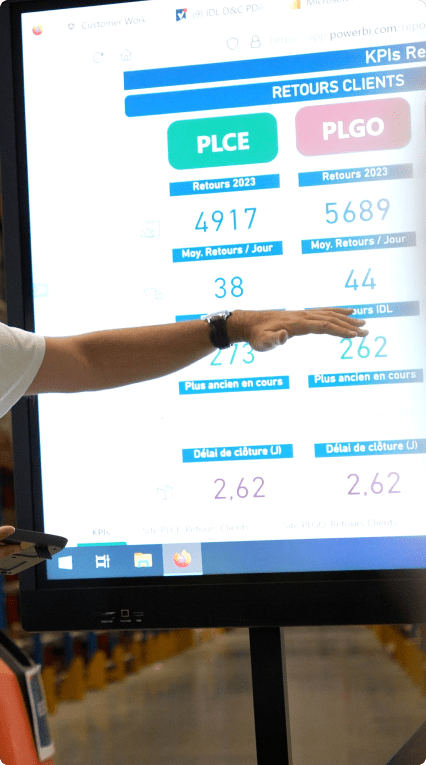

Collaborative management

Using collective intelligence to boost performance

We develop collaborative management methods with the aim of improving our operational processes. This reduces organisational silos and harnesses individual skills. Everyone plays an active role in this approach, thus strengthening employee engagement and giving meaning to their work.